Abs:

A novel high speed, high capacity electron-beam recording technique using nano technology in a Hard Disk Drive form factor is described. The e- beam source is a carbon nanotube (CNT) emitter and can be gated at rates up to several gigahertzes. The planned recording media is Phase Change with sub-nanosecond response times, and data read-out by Secondary Electron Emission is anticipated. The key parameters for generating the recording beam are described and a preliminary design is discussed in which the CNT based Read/Write head replaces the magnetic head in a standard Hard Disk Drive (HDD). The technique sidesteps limits associated with HDD technology and potentially provides far higher recording densities and higher data rates than possible with conventional magnetic-recording. The NanoTech Disk (NTD) approach may provide a path forward for HDD’s to the low nanometer mark scale.

INTRODUCTION

An approach to high performance data recording is discussed that provides nanoscale digital electron beam recording onto rotating disc media using a gated Carbon NanoTube (CNT) as a miniature precision electron-beam emitting source. With the ability to record marks in the low nanometer range and to achieve gigahertz modulation bandwidths per channel, this technology may provide a future upgrade path for Hard Disc Drives. In addition, the Nano Technology Disk (NTD) approach allows other options not readily available with magnetic technology, such as dense arrays of Read/Write heads and high performance archival HDD’s employing different media.

The goal is to demonstrate performance beyond that achievable with magnetic technology by showing digital data recording with sub 30nm, mark size and a platter capacity greater than 500 GB per square inch, (>1TB per 120 mm diameter, >350GB per 3.5 inch platter), and read/write rates of 100 Megabytes per second or greater. Future performance limits are probably far in excess of these initial goals as mark sizes of a few nanometers should eventually be possible. A secondary goal is to provide mass data storage with true archival properties in addition to re-writable media. Media constraints are also diminished as with a beam technology the head fly height can be much larger than in today’s HDD’s.

The basic approach is to adapt the existing hard disk drive technology shown in Figure 1.1 and obtain a major upgrade in performance by replacing the magnetic Read/Write (R/W) head at the end of the actuator arm with a CNT based NanoHead Assembly (NHA).

|

| Figure 1.1 Typical Multi platter Hard Disk Drive |

|

| Figure 1.2 Typical Disk Drive Configuration. |

Table 1.2. Comparison of CNT mark size with standard magnetic recording

Table 1.2 shows the relative track widths for magnetic vs. e-beam R/W heads, initially with the same down track bit length, i.e. data rate. This provides an immediate increase in data capacity of about 5X without changing the disk rotation rate, spindle motor or most of the drive electronics. Essentially, as shown in Figure 1.2, only the write driver and detector circuitry need change.

ELECTRON BEAM RECORDING

The art of recording analog or digital signal data by irradiating recording media with a focused e-beam and recording marks by thermal or electro-chemical means is well known and is widely used in some industries. Recording devices have been fabricated using a wide variety of media and have employed various means of generating a modulated e-beam, or a multiplicity of beams. In prior approaches the emitting source has been large compared to the desired recorded mark size requiring complex electron lenses and apertures to modify and focus the beam(s) onto the recording media. Further, these systems have invariably required the recording media and the e-beam source to be contained in the same vacuum so as to enable the electron beam to propagate through the system to the recording media without being substantially scattered by air molecules. Historical brightness values of 2x108A.st-1.m-2 V-1 have been achieved with e-beam currents of a few micro-amps and accelerated by a few tens of kilovolts, producing beam diameters in the micron range and limited by electron lens designs and emitted electron velocity spread. Current electron guns employ either a cold field emission gun or a Schottky emitter and result in e-gun assemblies far too large to be used in HDD’s a requiring an actuator mounted emitter as in Figure 1.1

The usefulness of an electron source in recording depends of several main parameters that include both the energy and the energy spread of the emitted electrons and the source brightness. A CNT sourced e-beam has both a significantly smaller virtual source and brightness more than an order of magnitude greater than other sources, i.e. about 3x109A.st-1.m-2.V-1. A multi-walled CNT diameter of about 30 nanometers is achievable and provides a small virtual source size, e.g. 20 nanometers. With a 50 volt potential the CNT tip emits up to 2 micro-amps that can be focused into a nearly collimated beam with a small range of electron velocities. Current is extracted by a voltage on an annular electrode about one micron from the CNT.

|

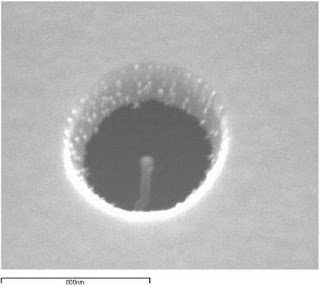

| Figure 2.1 CNT Emitter in Gated Cavity |

|

| Figure 2.2 SEM Photo of CNT Gated Emitter with 800nm Diameter Cavity. |

Figure 2.3 CNT Emitter Current vs. Voltage

NANOMETER SCALE RECORDING

With beam (e.g. laser) recording the recorded mark size is directly dependent on the beam wavelength and mark sizes much less than one wavelength are not practical. Electron optics obeys essentially the same propagation and focusing laws as light, but electrons have equivalent wavelengths much smaller than the wavelength of visible light, enabling far smaller recorded mark sizes.

Limiting beam related factors in the design of a CNT e-beam recorder are expected to be the spherical aberration of electron lenses used in the NS3 nanohead. Electron Optics software is available from MEBS that permits accurate design and evaluation of emitter head designs. Preliminary software analysis shows FWHM beams of 30nm or less are achievable with simple NanoHead designs and the initial gated CNTs obtained by NS3 NanoHead fabrication issues relate to voltage isolation at small dimensions and the need to accurately center electrodes to minimize beam distortions.

ELECTRON WAVELENGTH

Focused beam sizes limited by the lens ‘f number’ and the beam wavelength, with spot diameters less than one wavelength difficult to achieve. E-beam wavelengths are very small compared to 400nm blue light. The kinetic energy imparted to an electron of electric charge e and mass m falling through a potential V to a velocity s is given by eV = (1/2) ms2. The momentum of an electron is p = ms, so eV = p2/2m and p= (2meV)1/2.

ELECTRON BEAM PENETRATION

Previous E-beam writing systems have usually operated in vacuum as beam absorption in the path between the CNT and the media is an issue if a drive “flying head” approach is used at atmospheric pressure. A thin ‘window’ is required to protect the CNT emitter from oxidation, but a high fly height will allow most of the beam exiting a window to reach the media.

Penetration of low energy electron beams into a material depends on only the beam energy and the material density. Electrons will penetrate air to some small distance and will penetrate thin materials (membranes) which can act as windows. Each electron maintains its original energy until it collides with a molecule of the material. Hence the number of original electrons decreases as the beam propagates into the material. Figure 5.1 shows the relative loss of beam energy as a function of penetration distance for an electron beam where the extrapolated practical range is Rp and the maximum range is Rm. The useful range Ru, is taken to be where 75% of the beam energy is transmitted, at about 50% of the Practical Range Rp.

Figure 2.4 Particle Transmission Ranges

Figure 7 shows the Practical Range Rp, as a function of absorber density and the beam energy and applies to essentially all materials of any density, e.g. air or metal. Dividing a value of Rp by a material density in gms.cm3 gives the range Rp in cm.

Figure 2.5 Practical Range Rp vs. Beam Energy

ELECTRON TRANSMISSION IN AIR

The Practical Range, Rp, for electrons of energy 1keV is shown in Figure 9 as about Rp = 1.2x10-5 gm/cm2. The density of 300 0K dry air is about 1.2x10-3 gm/cm3, thus the Practical Range in air is 1.2x10-5 / 1.2x10-3 = 1x10-2 cm., or 100 microns. From Figure 7.1 with Rp = 100 microns, 75% of the electrons will remain unabsorbed after passing through about 50 microns. Reducing the air pressure by half will double the useful range, and doubling the electron energy will increase the useful range by slightly more than a factor of two.

ELECTRON PERMEABLE MEMBRANE

Material absorption characteristics enable the penetration of electrons through a thin window to be estimated. A typical window material, Silicon Nitride, of density 2.2 gm/cm3, has a thickness vs. electron energy relationship as in Figure 7.1. A window 0.025 micron (25nm) thick will pass 90% of a 1.5kV beam, although some limited scattering will occur. Beam scattering diminishes and transmission increases at higher beam voltages.

Figure 2.6 Silicon Nitride Window, Transmission vs. Thickness & Beam energy

Beam Absorption In Recording Media

The penetration of electrons into a material is determined by the density of the media in which the beam is propagating, regardless of the molecular weight of the material. Hence Figure 10.1 can be used to determine the minimum thickness of the recording layer needed to achieve complete absorption of the beam. Most metals have a density of approximately 7gm/cm3, giving a Practical Range of about 17nm for 500V electrons, with zero electron penetration beyond a material thickness of Rm (=1.2Rp), = 10.5nm. Higher velocity electrons will penetrate to an extent slightly greater than linearly, i.e. at twice the energy electrons will penetrate about 2.2 times as far. Typically the media absorption depth should approximate the recorded mark size.

DATA STORAGE APPLICATIONS

NS3’s primary goal is to establish the viability of the proposed approach and develop technology that avoids the limitations of current data recording technologies, with advanced performance in compact form factors. The developed technology should provide economically affordable high storage capacity, high read/write data rates, and fast access. The technology should be compatible with either removable or embedded media and with erasable or archival media. Products with all of these characteristics would apply to several large market segments now addressed by numerous current products such as hard disk drives, optical discs including CD-ROM’s and smaller discs, floppy discs, and all tape drive systems. Figure 1 shows the expected user capacity for various standard sized platters as a function of recorded mark size, with track spacing twice the mark size and PRML encoded data.

The CNT e-beam technology can be embodied in disk drive designs that fall into two principle categories.

Larger media disk sizes such as 120mm diameter (CD sized) using removable media and having capacities in excess of 1 Terabyte. Removable media implies in air media operation and therefore transmission of the e-beam through some air distance. This implies a CNT structure that is sealed in a vacuum tight head with the electrons passing through a semi-permeable membrane to the media. Another implication of in-air operation is the window must be within fifty microns or less of the disk surface for the beam to be adequately transmitted and may require a flying head, depending on the disk vertical run-out. Smaller fly heights permit greater transmission and lower beam spread due to scattering by air molecules. Current magnetic head fly heights are far less a about 10 nm.

2…Smaller disk sizes, 2.5 inches or less using embedded non-removable media. For this design option both the CNT head and media can be sealed in a single vacuum enclosure and an e-beam window is not required enabling smaller mark sizes. This also enables lower beam voltages and with lower disk vertical run-out a vertically fixed head can be used.

Either design approach is compatible with Read Only Media (ROM), Archival Media, or Erasable Media, depending on the intended application, although the various media require development.

One possible application is low cost mass storage of truly archival media (100+ years), that is removable and robotic compatible. Archival data storage is not viable using magnetic hard disc drives and the only other and currently employed option is magnetic tape. However, magnetic tape is not archival, nor is it cost effective due to the high cost of storing thousands of removable low data density tape cartridges in robotic servers. Further, data access is slow due to long tape wind times and tape is inherently a fragile media. Both issues are aggravated by thinner and longer tape used to increase cartridge capacity. Magnetic tape technology therefore no longer meets the need of capturing and retrieving terabytes of data per day and storing the data in an easily accessible archival database and is rapidly becoming obsolete. It would soon be abandoned except that, unfortunately, today there is no other alternative.

MEDIA CHARECTERISTICS

While the ability to record nanoscale marks by e-beam radiation is not in doubt, the read mechanism is less certain but can be based upon prompt emission of secondary electrons upon media irradiation by a read e-beam. Many media options exist as all materials exhibit secondary electron emission (SEE).The ratio of secondary to primary electrons (SEE coefficient, δ) is usually greater than unity and depends on the material and the primary electron energy. There is a specific electron energy that gives a maximum value of δ for each material. Initially δ increases with the primary electron energy until a maximum value is reached. At higher primary electron energies secondary electrons are generated deeper into the material and are reabsorbed resulting in lower δ values.

One possible archival media is a very thin layer of gold deposited on a thin layer of RbSb. The optimum electron energy for reading is about 300-450 volts, at the peak SEE output of the RbSb sub-layer, and for unwritten media the lower gold SEE ratio at this voltage will apply and few electrons will be emitted. Writing is accomplished by melting both layers so the gold is absorbed or mixed into the RbSb layer. On data read, without the gold top layer, the SEE response of the RbSb will dominate and the readout SEE rate will be about 8X greater as shown in Figure 10.1.

The SEE outputs are ‘prompt’ and occur picoseconds after e-beam irradiation. Similar media designs using RbSb can be considered using a variety of low δ SEE materials; tin, lead, indium, gallium etc. A similar approach could use a two layer media with Rubidium deposited over Antimony. With an under layer of Antimony (Sb), and a layer of Rubidium (Rb, δ =0.9) on top, the unwritten response would be low, but on melting the layers would mix, and after cooling increase the SEE response to that of RbSb at δ =7.1. Control of the initial deposited layer thicknesses provides the Rb, Sb mix for maximum SEE output shown in Figure 10.2.

A PRELIMINARY DESIGN

The initial design approach employs a rotating disk with an e-beam sensitive media layer and a CNT based read/write head assembly 0.5mm in diameter, 1mm long, mounted on an actuator arm. The entire CNT/electrodes structure is located in a vacuum housing with the CNT at one end and the e-beam exiting the structure through a semi-permeable membrane at the other. The multi-walled CNT of any chirality has a length of about 800nm and is nominally 30nm in diameter. A first gating aperture electrode is located concentric to and 1µm from the CNT tip and is nominally at a 50 volt potential to the CNT, providing a beam current of 0.1 micro amps, with over 1µA available. A second concentric focusing electrode is distant 1 µm from the gating electrode and at the CNT potential. A window 20 nm thick is located as a seal at the end of the vacuum enclosure and 1mm from the CNT. An aperture electrode is located inside the window at a positive accelerating voltage of 1.5KV. The focusing voltage is adjusted so the e-beam is brought to a slow focus 10-20 microns from the window exterior with the media 15microns from the head structure.

CONCLUSION

Carbon nanotube technology is relatively new but has advanced rapidly the design and fabrication of a read-write head is now viewed as a design development task. Implementing appropriate media entails some small risk as does achieving the desired track following accuracy. The use of a CNT based Nano Head Assembly enables several innovations not practical with today’s HDD’s. These are possible as CNT emitters can be grown in close proximity to each other. Mark detection schemes rely on electron interaction with the media, an area of little data, but offering many media possibilities.

Download this Seminar Report

Embed-upload: Download

password: be

0 comments:

Post a Comment

Thanks for your Valuable comment